Expert Cathodic Protection System for Ships: Protect Your Vessel from Corrosion

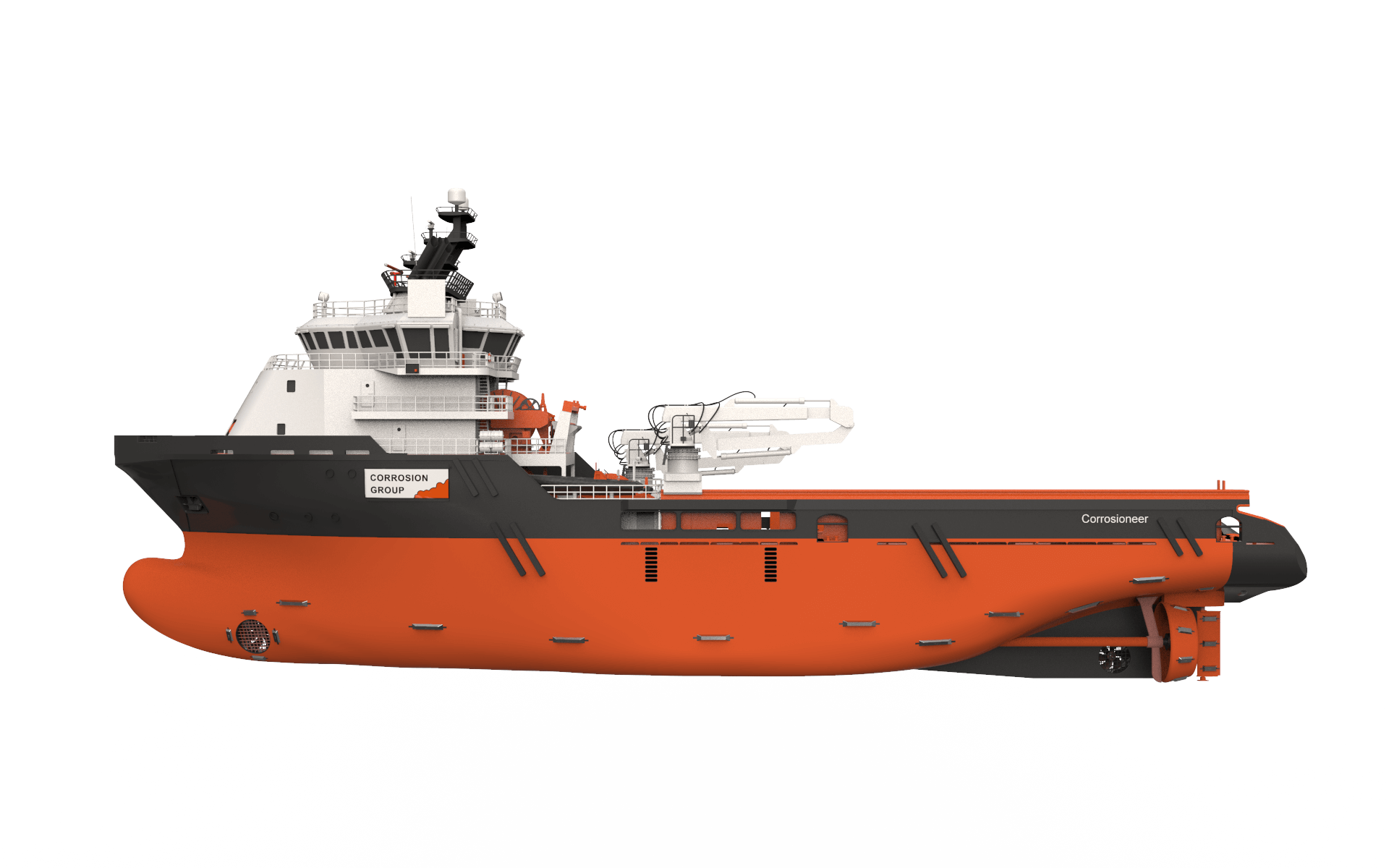

As a shipowner or operator, ensuring the longevity and safety of your vessel is of the utmost importance. One of the most effective ways to do this is by implementing a cathodic protection system.

NoCor™ Control Unit

Our company specializes in designing and implementing custom cathodic protection systems for ships of all types and sizes. We use the latest technology and industry-leading techniques to ensure that your vessel is protected from the corrosive effects of saltwater and other elements.

Our team of experts has extensive experience in all aspects of cathodic protection design and implementation, from initial inspections and assessments to ongoing maintenance and monitoring. We work closely with our clients to understand their specific needs and design a system that is tailored to their vessel and operating environment.

In addition, we offer a wide range of services to support the overall performance of your cathodic protection system, including technical advice, installation, commissioning, and maintenance.

If you're looking for a reliable and effective cathodic protection system for your ship, look no further. Contact us today to learn more about how we can help protect your vessel from corrosion and prolong its lifespan.

How does a Cathodic Protection system for a ship work?

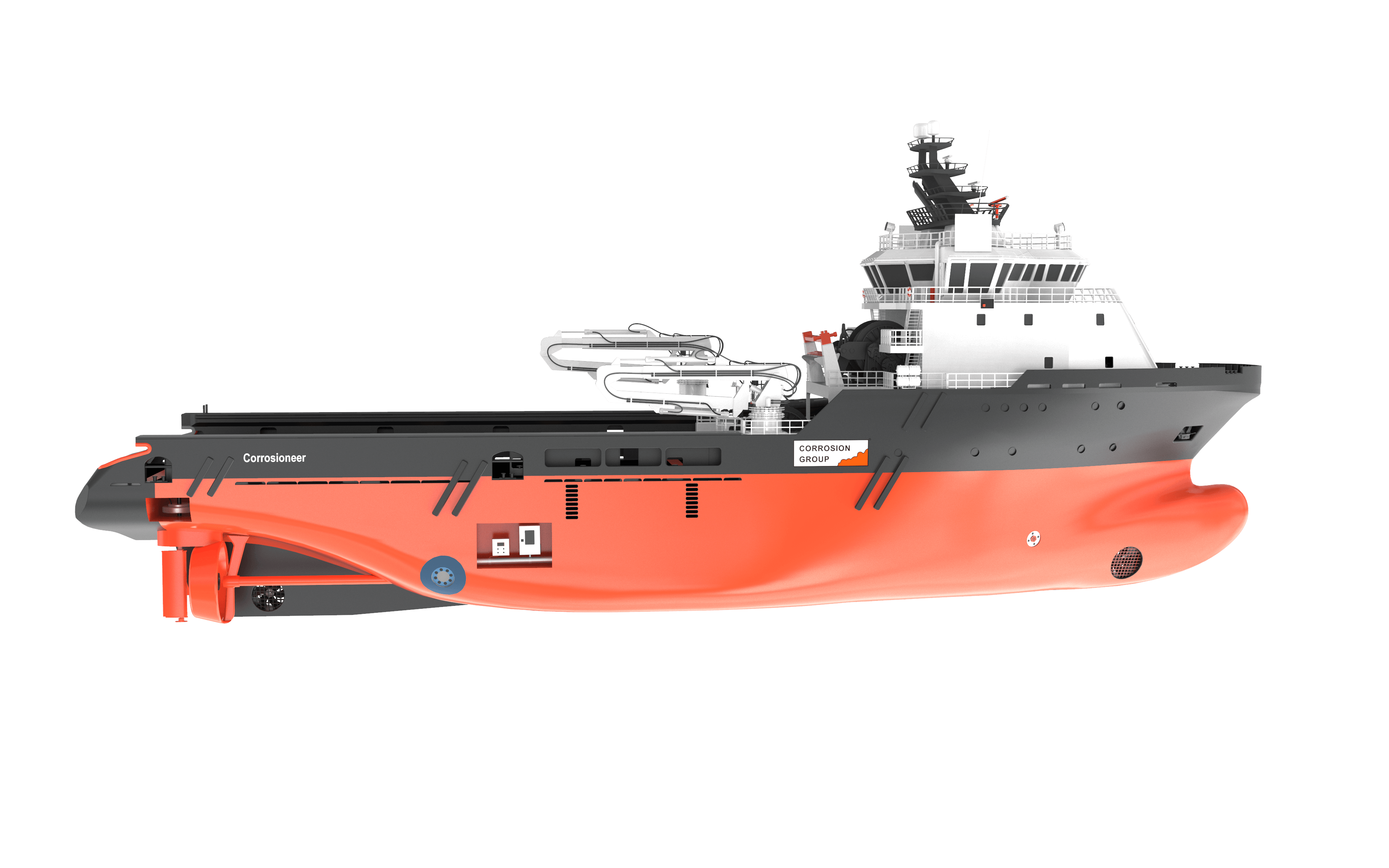

All metal vessel parts, submerged in water can be protected by our ICCP systems. Comparing to large numbers of sacrificial anodes, ICCP systems are superior. Both economically and in regard to design life. Where sacrificial anodes costs more in proportion to the area to be protected, ICCP systems increases less that proportionally.

ICCP systems work by cyrrent flowing from a DC power source trough anodes of various materials. Adding a protective current to the hull (cathode) from the sacrificing material (anode)

Clear advantages of ICCP systems versus sacrificial anodes:

- Cost effective

- Controllable protection levels

- Long life anodes

- Requires minimum maintenance

- Higher driving voltage

- Connectable to VMS via RS485 and RS232

- No drag as by sacrificial anodes, this means lower fuel consumption.

- Unlimited protection capacity (accepts higher coating breakdown than sacrificial anodes)

Certifikat