Pipeline Corrosion Prevention Methods for Oil and Natural Gas Pipes

Due to several pipeline explosions over the past few years, pipeline corrosion prevention for oil and gas pipelines has become a “hot” topic within the energy sector. Both for the devastating damage that it causes but also for the lives it takes, in our opinion, it’s a subject worth discussing.

Here are some of the most successful pipeline corrosion prevention methods

Leaving metal pipelines exposed to the environment is always a dangerous path to take, it doesn’t matter if you are dealing with chemicals, oil, gas or simply just water. Leaving the line unprotected will end up with heavy repair costs and a great hazard for both people and the environment.

The metals used when installing different pipelines are usually very prone to corrode, whether stainless or not, there will always be some kind of corrosion taking place. The question is, can you limit or completely eliminate the problem?

If you ask us at Korrosionsgruppen AB, a successful corrosion control program is always an ongoing task. Essentially, what you put in is what you get out.

It all starts with a well designed and well installed pipeline cathodic protecting system and continuous monitoring and maintenance.

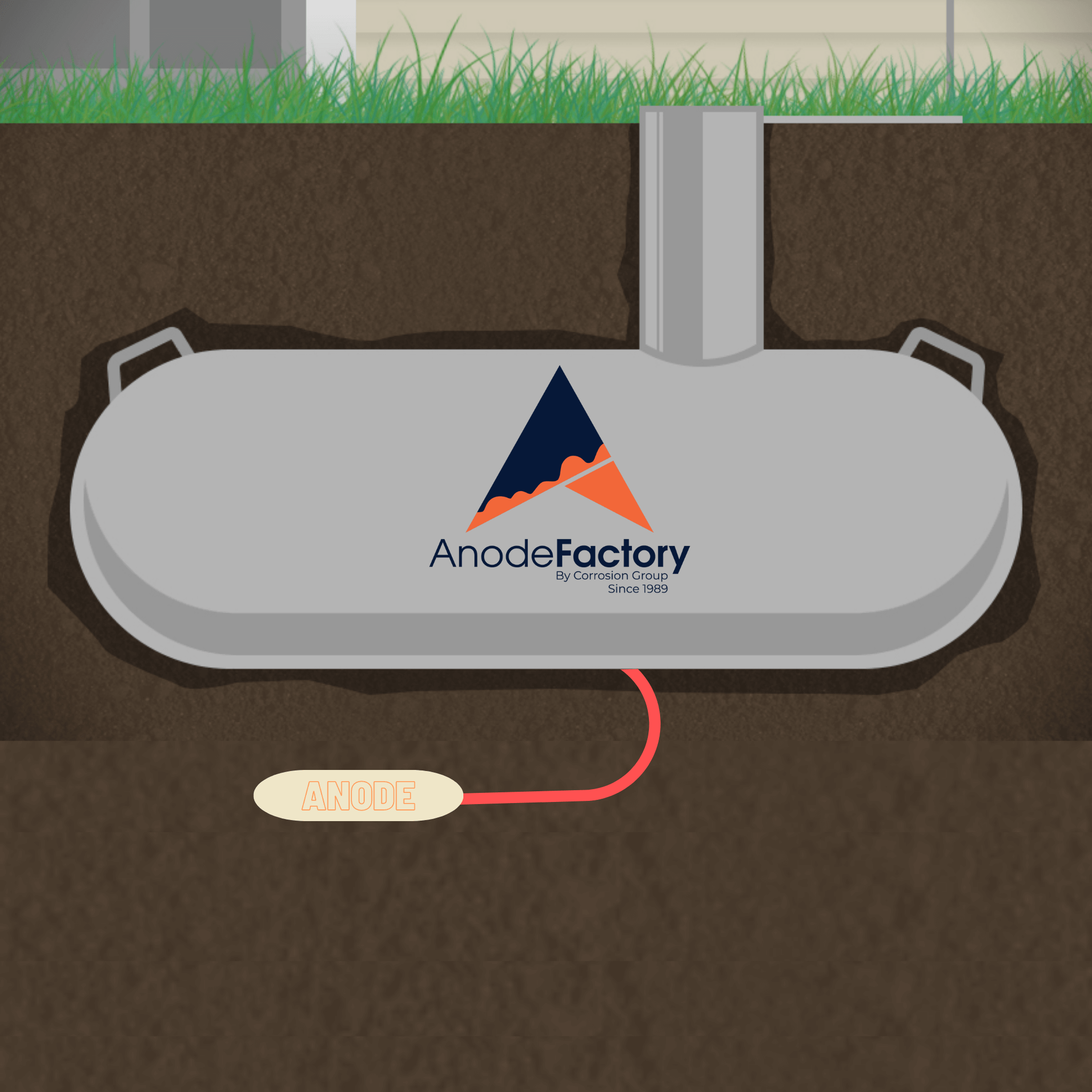

1. Cathodic protection

Simply explained, cathodic protection is a method to neutralize corrosion on any metal object situated in an electrolyte. When it comes to pipelines, its often used when the object is buried or under water. It is never too late or to early to prevent or stop corrosion. On new pipes, you can neutralize it instantly, and on old ones you can stop it from progressing. Cathodic protection (CP) is a method to control corrosion by using a direct electrical current which neutralizes the external corrosion typically associated with metal pipe.

2. Choosing the right coating and linings (passive corrosion prevention)

In order to achieve a low leakage load, the direct ground contact must be reduced. This is done by coating the pipeline and avoiding or preventing conducting connections with installations with low grounding resistances. In order to achieve a low leakage load on a pipeline, the coating must be of high resistance quality. Are you looking for help to protect your pipelines against corrosion and future attacks? You can read more about our corrosion services here Read more about corrosion on pipelines here