Our systems

Galvanic corrosion protection

In this approach, a metal with higher reactivity, usually zinc, is connected to the object that needs to be protected from corrosion. This process initiates the creation of a galvanic cell. As a result, the corrosion occurs on the zinc instead of the object that you would like to protect.

About (ICCP)

Also known as Impressed Current Cathodic Protection (ICCP), takes advantage of an external power source to carefully apply a controlled electric current to the metallic object in question. This technique allows the current to be directed to transform the metallic surface into a cathode.

Coating

The process of coating, which is also referred to as surface treatment or simply coating, holds significant importance in the realm of corrosion protection. Its primary purpose is to safeguard metallic surfaces from the detrimental impact of corrosion, which can lead to degradation and weakening of materials over time.

Different areas of application

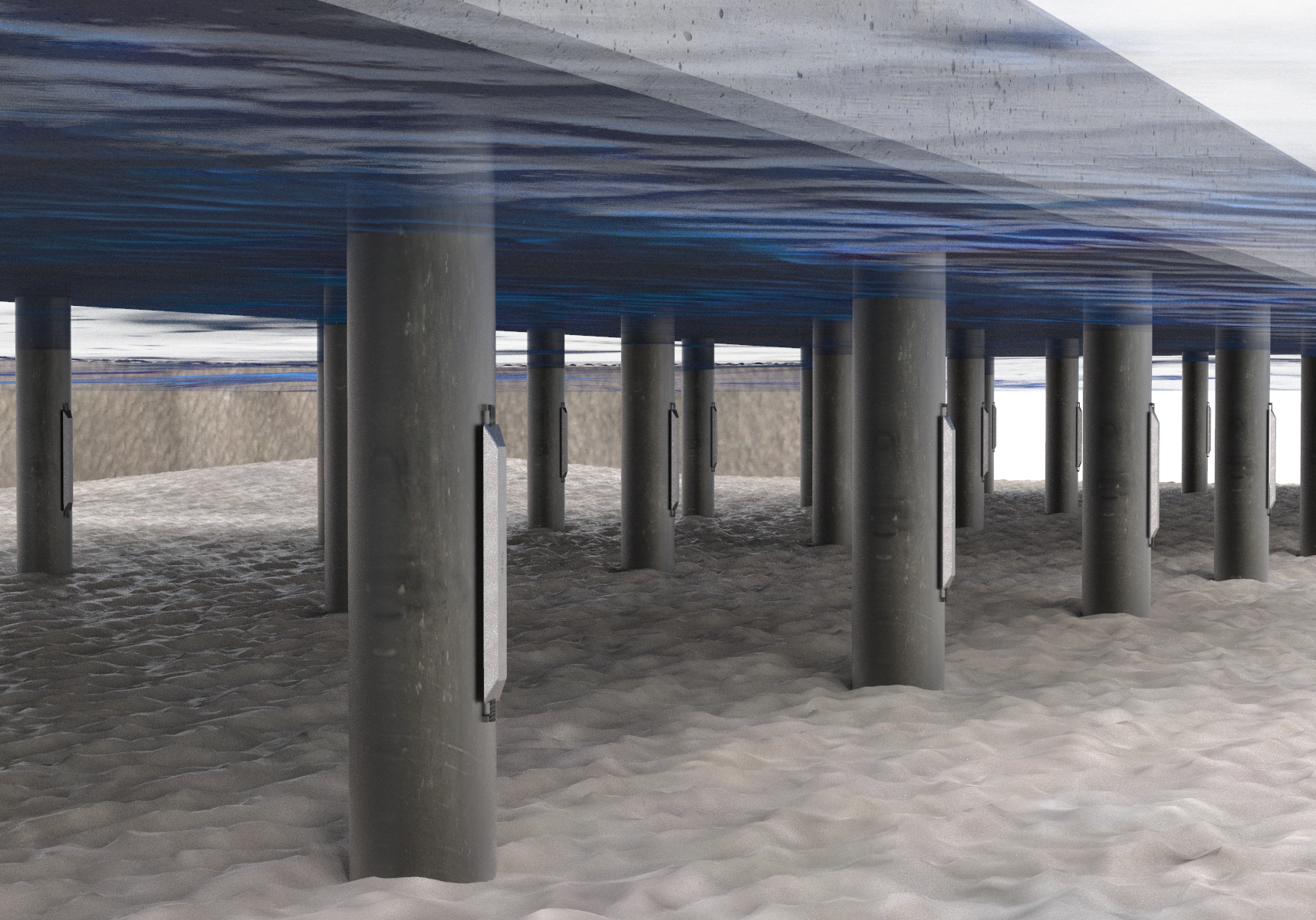

Infrastructure

Pontoons/Barges

Harbours

Piles

Are you curious to learn more about this process and how we can increase the sustainability of maritime objects?

Contact us for a project planning today, and avoid expensive maintenance costs!