Corrosion in harbours, with concrete head beams

Steel pontoon in quay

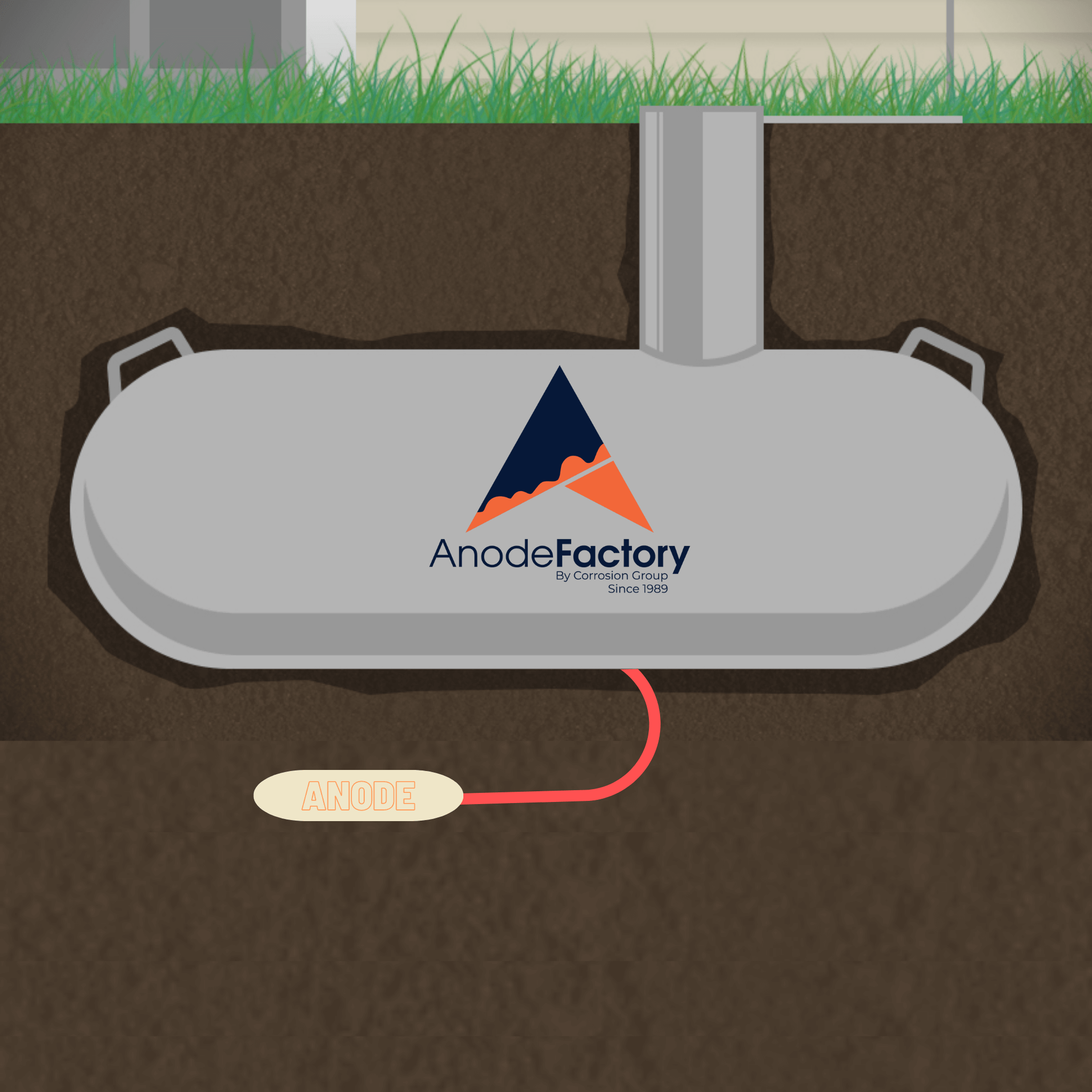

Initially, it is possible to stop or delay the progress of corrosion on both new and older protective objects.

Steel pontoons in berths are effectively protected by cathodic corrosion protection. On the west coast and in the Baltic, sacrificial anodes are usually used. North of Gävle, corrosion protection with applied current is normally used because the resistivity of the water here is so high.

When designing, the surface is first determined by the protection object and the resistivity in the water. Based on this, it is determined whether sacrificial anodes or cathodic protection with applied current are to be installed. The resistivity can e.g. differ significantly if the protection object is in

The mouth of any watercourse or if there is any discharge of contaminated water. If applied current is selected, a sample polarization is continued. Next, the anode design, material and number and current source are determined. When installing cathodic protection on the quayside, it must be remembered, among other things, that the anodes must be mounted firmly because sea and ice can affect the attachment of the anodes and possible cables. In a galvanic protection (sacrificial anode), aluminum is normally used on the west coast and up to Gävle.

Floating bridges, reinforcement in concrete, floats, steel piles, jumping towers, buoys, dives, pipes and other metallic structures can also be protected with cathodic protection. All structures contained in an electrically conductive electrolyte such as water, soil or concrete have

prerequisites for protection.

Read more about how we protect steel structures in water here!