NoCor® System - Fully Automatic & maintenence free

All metal parts of a ship under water, can be protected by the NoCor® Cathodic protection system. Compared to a larger number of sacrificial anodes, Impressed Current Cathodic Protection (ICCP) systems such as NoCor® can be both more economical and technically superior in terms of weight and lifespan. Often, a NoCor® ICCP system means that sacrificial anodes can largely be excluded from the hull. This, in turn, leads to a significant reduction in weight and, consequently, less fuel consumption.

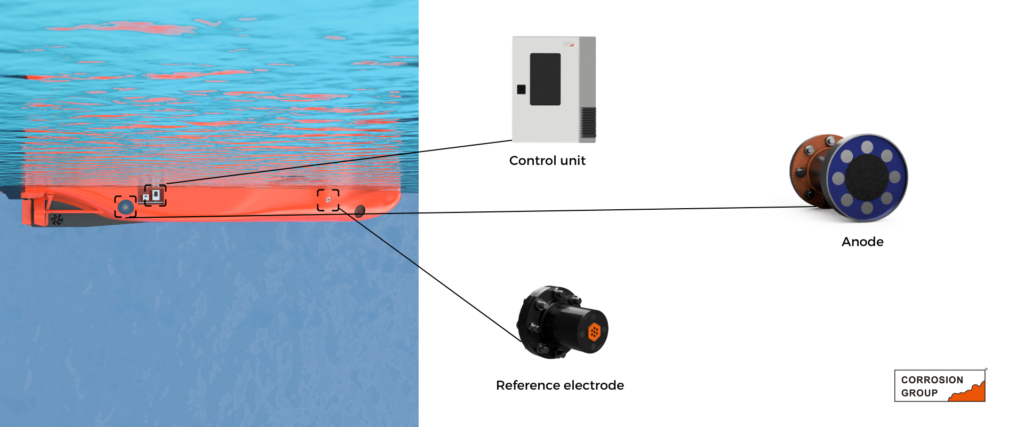

NoCor® ICCP systems work by a rectifier sending out a protective current via anodes (anode) which then supplies/sends the current to the hull (cathode) and other parts one wants to protect. In this way, corrosion is prevented.

Anodes

The anode types used in an NoCor® system may be linear, elliptical or circular, all of which are relatively inert.

All types of anode are provided with a cofferdam, incorporating a double gland assembly approved by the classification societies, to ensure a watertight hull penetration for the anode cable.

Reference Electrodes

At least two and sometimes four reference electrodes are fitted in the NoCor® system and these can be surface mounted or recessed. Both types incorporate a block of high purity zinc which, because of its robust construction and stable electrochemical characteristics, is an ideal material for reference purposes.

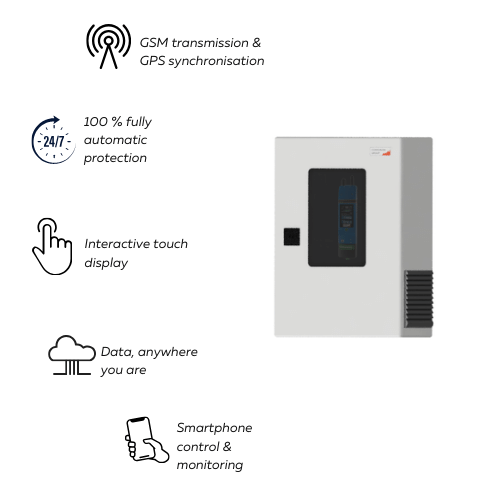

Controller Power Unit

The controller power unit is self-contained in a cabinet situated in the engine room or other convenient space. The NoCor controller is 100% automatic and maintenence free.

Power supply is from the ship's AC mains which is transformed and rectified to produce the DC current required for cathodic protection.

Full electrical protection is provided on input whilst output fuses are fitted in each anode circuit. All components are readily accessible within the drip-proof steel enclosure.

Remote Monitoring System

At Corrosion Group, we have implemented a cutting-edge remote monitoring system for cathodic protection for maritime operators, ensuring efficient management of corrosion and maintaining a safe environment. Our system offers real-time updates, alerts, and continuous data collection, empowering asset owners to optimize operations and minimize risks associated with corrosion damage. Our monitoring & control system, will do the job for you. Install and forget about it! it will let you know if something is wrong...

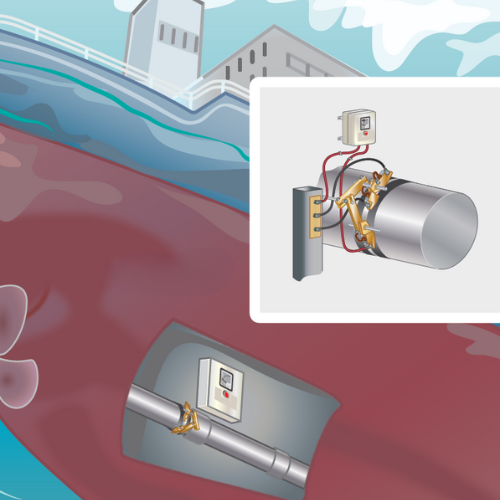

Propeller shaft grounding

Propeller Shaft Grounding and Monitoring Assembly

This assembly ensures good electrical contact between the propeller and propeller shaft and the ship's hull. This, in turn, inhibits dezincification of bronze propellers, and provides a level of protection to propellers made of other materials. It also protects the shaft bearings from corrosion.

The assembly comprises a silver inlaid copper band, clamped to the shaft and a brush assembly. High silver content brushes running on the silver strip provide electrical continuity with the hull. Monitoring panels can be supplied for single and twin shafts which can be used as stand alone monitoring systems.

Propeller shaft slip ring assembly

Propeller shaft monitoring system

Installation, Commissioning and Service

Typical NoCor® installations that for 'aft' systems is applicable both for small and large vessels, whereas the forward system applies only to large vessels whose length necessitates the use of a supplementary system near the bow section. For forward systems it is necessary to recess anodes to protect them from mechanical damage and to reduce drag.

Once commissioned, an NoCor®system operates automatically, requiring no adjustment.

Certifikat